Our services in injection molding simulation of thermoplastics include: fill, pack, cool, and warpage analysis.

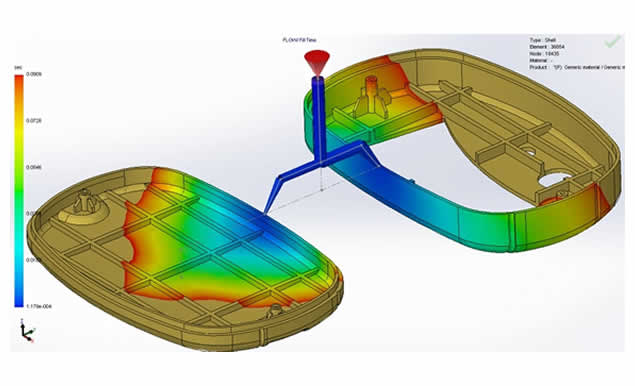

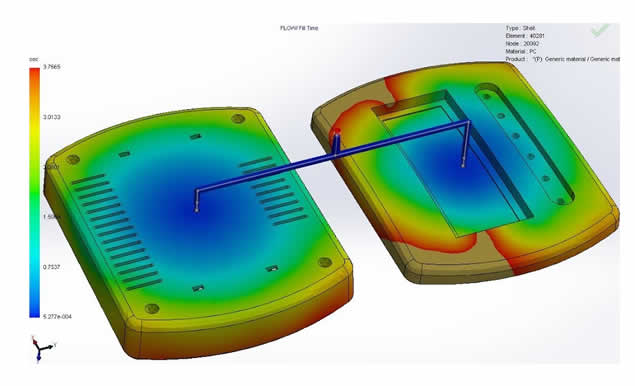

Fill

- Prediction of injection pressure

- Detection of weld lines, air traps

- Visualization of 3D filling pattern

- Evaluation of shear rate, stress, velocity

- Optimization of gate location, gate size, process parameters

- Detection of short shot and filling imbalance

- Prediction of fiber orientation

Pack

- Evaluation of pressure and temperature distribution

- Estimation and optimization of gate freeze time

- Optimization of packing time, packing pressure, switch over

- Visualization of shrinkage behavior

- Estimation of clamping force

- Evaluation of part density and weight

Cool

- Prediction of hot spots

- Evaluation of temperature distribution and cooling efficiency

- Determination of required cycle time

- Detection and resolve cooling imbalance

- Optimization of cooling system

Warpage

- Prediction of part shape

- Evaluation of shrinkage and thermal induced residual stress

- Displayment of part deformation

Please send your quote via our form